Researchers find chicken feathers make fuel cells more cost-effective

The membrane consists mainly of biological keratin, which is environmentally compatible and available in large quantities.

November 6, 2023

The food industry generates enormous amounts of waste and by-products, including from poultry production. Each year, some 40 million tons of chicken feathers are incinerated. This not only releases large amounts of CO2, but also produces toxic gases such as sulphur dioxide.

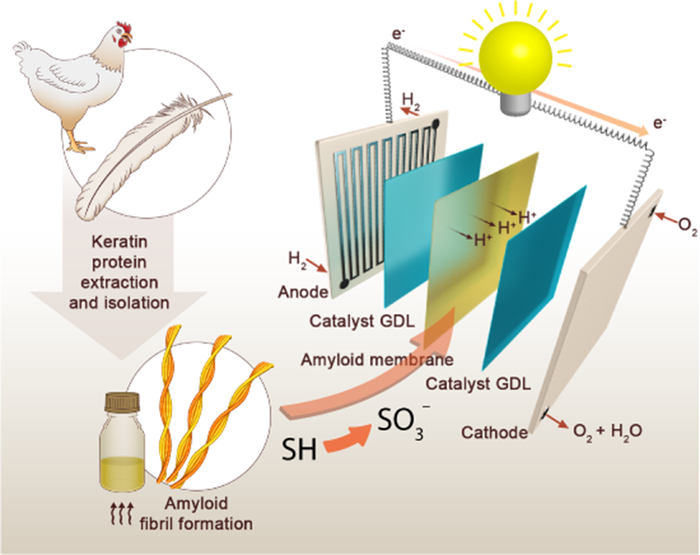

Researchers at ETH Zurich and Nanyang Technological University Singapore have now found a way to put these feathers to good use. Using a simple and environmentally friendly process, they extract the protein keratin from the feathers and convert it into ultra-fine fibers known as amyloid fibrils. These keratin fibrils go on to be used in the membrane of a fuel cell.

Fuel cells generate CO2-free electricity from hydrogen and oxygen, releasing only heat and water. They could play an important role as a sustainable energy source in the future. At the heart of every fuel cell lies a semipermeable membrane. It allows protons to pass through but blocks electrons, forcing them to flow through an external circuit from the negatively charged anode to the positively charged cathode, thereby producing an electric current.

A sustainable membrane is produced from the keratin in chicken feathers for use in a fuel cell. (Graphic: ETH Zurich / NTU)

Making good use of industrial waste

In conventional fuel cells, these membranes have so far been made using highly toxic chemicals, or “forever chemicals,” which are expensive and don’t break down in the environment. The membrane developed by the ETH and NTU researchers, on the other hand, consists mainly of biological keratin, which is environmentally compatible and available in large quantities – chicken feathers are 90% keratin. This means the membrane manufactured in the laboratory is already up to three times cheaper than conventional membranes.

“I’ve devoted a number of years to researching different ways we can use food waste for renewable energy systems,” says Raffaele Mezzenga, professor of Food and Soft Materials at ETH Zurich. “Our latest development closes a cycle: we’re taking a substance that releases CO2 and toxic gases when burned and used it in a different setting: with our new technology it not only replaces toxic substances, but also prevents the release of CO2, decreasing the overall carbon footprint cycle."

Versatile application

However, there are further challenges to overcome before hydrogen can become established as a sustainable energy source. “Hydrogen is the most abundant element in the universe – just unfortunately not on Earth,” Mezzenga says.

Since hydrogen doesn’t occur here in its pure form, it has to be produced, which requires a great deal of energy. Here, too, the new membrane could serve well in the future, because it can be used not only in fuel cells but also in water splitting.

In a process known as electrolysis, direct current is passed through water, causing oxygen to form at the positively charged anode, while hydrogen escapes at the negatively charged cathode. Pure water isn’t conductive enough for this process and often requires the addition of acids. The new membrane, however, is permeable to protons and thus enables the particle migration between anode and cathode necessary for efficient water splitting, even in pure water.

Patent pending

The researchers’ next step will be to investigate how stable and durable their keratin membrane is, and to improve it if necessary. The research team has already filed a joint patent for the membrane and is now looking for investors or companies to develop the technology further and bring it to market.

You May Also Like