Do you have confidence in your phytase enzyme?

With pressure to reduce feed costs and enhance optimal performance, which matrix would you put your confidence in?

January 17, 2024

Authors: Tara York, Carrie Walk and Tom Dale

For most broiler nutritionists, the primary nutrient that comes to mind when feeding a phytase enzyme is phosphorus (P). This, of course, is no surprise as phytase enzymes are primarily fed in animal diets to degrade phytate for the release of phytate-bound P. Over the years, our knowledge of phytate degradation has evolved. Today we have a greater understanding of the quantity of phytate P in our ingredients and the P equivalence of phytase enzymes, as it is related to the phytate P content and its degradation (Selle et al., 2010). With increased phytate degradation, however, comes increased ileal amino acid digestibility, calcium (Ca) digestibility, enhanced energy utilization and increased myo-inositol, resulting in what are now known as the “extra-phosphoric” effects of phytase.

Yet, P remains one of the most expensive nutrients in the diet. As nutritionists seek to enhance animal performance or lower feed costs when incorporating a phytase enzyme, having confidence in the phytase and the P matrix applied becomes even more important.

Conventional Matrix Values are Based on Averages

Phosphorus is an important nutrient for a variety of biochemical pathways, physiological processes, and skeletal integrity (Dijkslag et al., 2021). It is well-established that reducing dietary P levels can lower bone ash as well as feed intake and body weight gain. In the past, nutritionists were very conservative with the phytase matrix applied and seldom fed beyond the standard dose of 500 FTU/kg, with minor P and Ca contributions given. Today, many nutritionists feed 1,500 FTU/kg of phytase with higher mineral and amino acid matrices to reduce feed costs. Therefore, it is important when establishing phytase matrix values, especially P, that the phytase enzyme must restore growth rate and bone ash to levels that would have been achieved before the matrix value of P was removed. As nutritionists rely on phytase suppliers to provide the enzyme matrix based on the dose level fed, having confidence in how the matrix value was derived is key to ensuring nutrient savings and enhanced performance.

In phytase matrix studies, the parameters normally measured to determine how effective a phytase is at replacing inorganic P are growth rate, bone ash, and digestibility. Generally, birds are fed a P-deficient diet, which is then supplemented with graded levels of phytase and ideally graded levels of an inorganic phosphate source. The graded levels of inorganic P allow construction of a standard curve comparing the effect of the inorganic P levels with growth rate and/or bone ash of each dose of the phytase. As a result, a P matrix is determined (Adeola, 2010). However, it is important to ask how much of a safety margin has been placed on the P matrix value once it has been established. The answer may surprise many because the P equivalence estimated and incorporated into a phytase matrix is usually just an average of the parameters studied (bone ash, growth rate, and digestibility) with no safety margin applied at all.

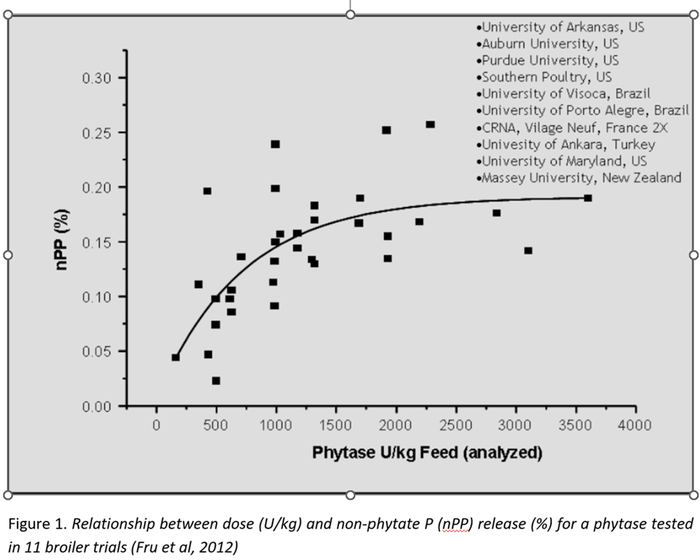

An example of how most phytase matrices are developed is demonstrated by Fru et al. (2012). In this work, the non-phytate P (nPP) matrix for a given dose of phytase was estimated from 11 different studies and compiled into one graph, where bone ash, gain, feed conversion ratio (FCR), and P digestibility were used as the measured parameters (Figure 1). In this evaluation, the average matrix value determined for 1,000 FTU/kg of phytase was 0.15% nPP; however, the range of responses varied from 0.08% to 0.24% nPP at 1,000 FTU/kg. In practice, this means that, on many occasions, not enough phytase would have been fed to recover the performance that was needed if the average P matrix value of 0.15% nPP was applied.

Photo submitted by AB Vista.

As nutritionists begin to optimize their feed formulations and rely on the nutrients released from phytate degradation, is an average value good enough? A 50% confidence limit is the current industry standard. Simply put, this means 50% of the time the enzyme would deliver the provided matrix, yet 50% of the time it would deliver less, resulting in an under-delivery of P in one out of every two occasions. As nutritionists move towards fully utilizing phytase enzymes at higher dose levels to maximize feed cost savings and applying higher nutrient matrices, shouldn’t our confidence in the enzymes’ ability to deliver these nutrients be more than that of a 50:50 coin toss?

Built-in Safety Margin with Quantum Blue

When first introduced into the market more than 10 years ago, Quantum Blue, an enhanced E. coli-derived phytase, was intentionally released with a built-in safety margin for the standard 500 FTU/kg of phytase. This statistical safety margin, with a 90% confidence limit, was applied to the average matrix, to provide “built-in” confidence. This means that 90 out of 100 times, 500 FTU/kg will be sufficient to achieve 0.15% available P (avP) and will undoubtedly perform better than the average 50% confidence limits currently used by many.

In 2023, an updated holo-analysis for Quantum Blue was conducted using 138 broiler trials (1,686 data points) to reevaluate and confirm the avP provided when feeding 500 FTU/kg of Quantum Blue. Unlike a meta-analysis, a holo-analysis includes all the dietary, husbandry, and management factors from all trials conducted, without cherry-picking the best trials, allowing for a more comprehensive evaluation of the data. Using body weight gain and bone ash, it was determined that the average avP release for 500 FTU/kg of Quantum Blue was 0.19% avP. Upon applying the 90% confidence limits, the published avP value of 0.15% was re-confirmed. Therefore, nutritionists can formulate with 90% certainty the true avP value for 500 FTU/kg of Quantum Blue to fall within this range (0.15 and 0.195 avP%).

Put Your Confidence in the Right Matrix

For phytase enzymes that provide only an average avP value, this means the true, real-world value will likely fall much lower than indicated more than 50% of the time. With pressure to reduce feed costs and enhance optimal performance, which matrix would you put your confidence in? A 50:50 toss of the coin or an enzyme you know will deliver 90% of the time!

Reach out to an AB Vista representative at [email protected] to learn more about QuantumBlue and build your phytase confidence today.

You May Also Like