USDA research yields big results in food safety

Overview of USDA research efforts highlights new discoveries in food safety, including against salmonella and campylobacter.

4 Min Read

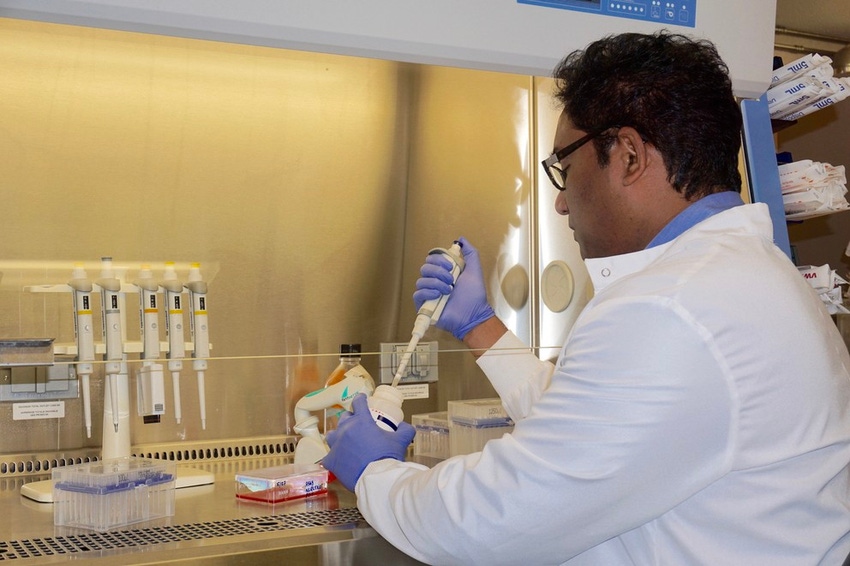

Suresh Kuchipudi, associate professor of virology in Penn State's College of Agricultural Sciences, conducted research to determine if little brown bats can be asymptomatic carriers of avian and human influenza viruses. Here, he infects cells with influenza virus as part of those studies.Image: Sanjana Kuchipudi

About the Author(s)

Subscribe to Our Newsletters

Feedstuffs is the news source for animal agriculture

You May Also Like