Whey facility will clean liquid co-product and provide career training for university students.

April 6, 2016

When the Washington State University creamery makes cheese, only 10% of the milk purchased from the university's Knott Dairy winds up in the final product, but that will change when ground is broken on a new expansion at the creamery.

Before, 15,000 lb. of milk resulted in 1,500 lb. of cheese, and the remaining liquid, called whey, was a waste product.

A new whey processing facility, which will be attached to the creamery and Ferdinand's Ice Cream Shoppe, will filter out organic material from the whey. The resulting water will be clean enough to simply flow down the drain.

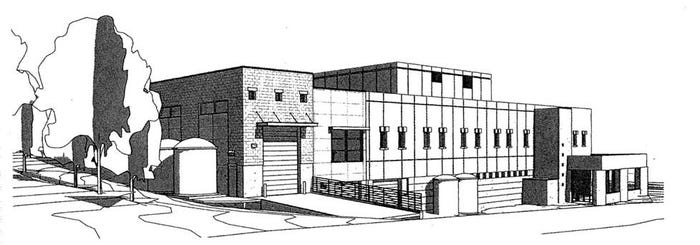

A rendering of the creamery with the new whey processing facility and truck bay.

“For the past several years, we’ve pumped our whey into tanker trucks and hauled it out to the dairy farm,” said John Haugen, creamery manager. “Now, we’ll be able to separate all the proteins and other components, just like commercial cheese factories.”

That’s useful because, in addition to selling cheese, the creamery is a teaching facility. It provides paid training for students who want to work in the dairy industry, and having hands-on experience in whey processing will be an advantage in an industry that’s always looking for uses for leftover whey, Haugen said.

The new facility will include a reverse-osmosis system and other membrane filtration equipment, along with training space and administrative offices. It will house a receiving bay large enough to provide important safety and security measures for the two tanker trucks operated by the creamery.

Building construction will cost up to $4 million, not including equipment. The creamery is funding the construction, which is expected to take nine months to complete.

Haugen is planning for a grand opening in October or November.

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)