When feed cost energy is scrutinized, phosphorus continues to be among the most expensive nutrients within the ration.

March 15, 2021

Sponsored Content

By Franco Mussini, PhD, DVM Technical Director, North America, Danisco Animal Nutrition - IFF

Independent of normal production conditions or during a global pandemic, poultry producers across the world continue to share the same goal; producing high-quality protein at the lowest cost possible. Feed is usually the first place they look for savings when trying to reduce meat prices as it represents the number one cost in poultry production. When feed cost energy is scrutinized, crude protein/amino acids and phosphorus, continue to be the most expensive nutrients within a ration. Consequently, past and ongoing studies on the proper level of digestible amino acids and energy requirements for these nutrients, have been adjusted so that any change will increase the per-pound cost of meat. Alternatively, Phosphorus (P), is the next significant opportunity for producers to maximize their return on investment.

For poultry in North America, phosphorus requirements as well as ingredient phosphorus availability for the bird, has historically been measured using the Available Phosphorus (Av P) system. Though it has been successfully used to feed billions of birds over the years, the system is not perfect. An alternative to the Av P system is the Digestible Phosphorus (Dig P) system.

Why Digestible Phosphorus over Available Phosphorus?

Different reasons which are outlined below, make it an easy decision to switch Phosphorus bioavailability systems.

Accuracy

P availability has been a subject of study for over 80 years now and a large number of studies have been conducted across multiple research centers. As a consequence the Available Phosphorus (Av P) system was developed. Though in use for many years, this system, in the way it is being utilized today, has some flaws that make it inexact.

Analysis of the studies that led to the implementation of Av P system show a lack of standardization that makes it very difficult to consolidate the information in one table of ingredient values and bird requirements. This is not a new challenge for poultry nutritionists. Nelson et al reported this problem in 1990 but it was Shastak and Rodehutscord who investigated this topic in depth and concluded that it was not possible to combine these data. In their review the different problems related to Av P are covered. The first problem they found was the different response criteria utilized to assess P availability from different ingredients. Body weight gain, bone ash, bone strength or phosphorus blood levels are all qualitative criteria used to characterize ingredients but cannot be utilized interchangeably nor compared to quantitative methods like P retention or prececal digestibility. Another problem identified was that multiple inorganic sources were used as standard references to develop Av P values for raw ingredients. Each one of these standards have a different bioavailability and consequently the values determined for one ingredient using mono sodium phosphate for example, cannot be compared to the values of another ingredient that was generated using disodium phosphate for example.

In order to overcome this problem, a Dig P phosphorus system was developed to provide more accurate values for ingredients as well as requirements for birds. The Central Veevoederbureau, commonly known as the CVB, implemented this system in 1997 and supported it with values for most ingredients. Later, in 2013, The World Poultry Science Association refined the protocol for the determination of phosphorus availability recommending the use of prececal digestibility.

Feed cost savings

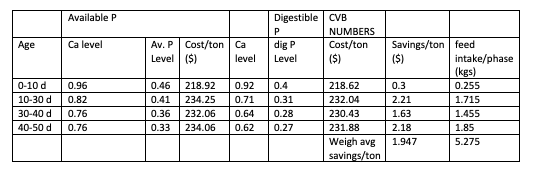

The correct assessment of phosphorus availability to the bird for feedstuff not only ensures the right inclusion of this mineral but also reduces the cost of poultry rations. An analysis conducted using industry benchmark data of May 2020 shows savings of $1.947/ton for an average broiler feeding program.

Table

Proven success

The Dig P system has been in place in most European countries as well as in poultry companies in other countries around the world for many years now. Producers currently in the process of switching from Av P to Dig P attest to the positive results this system brings.

Environmental impact

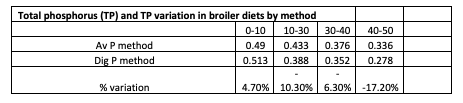

Use of Dig P reduces the utilization of finite inorganic sources of P but also reduces the excretion to the environment of this mineral. Same diet analysis shows a total phosphorus reduction of kilograms/ton when moving from Av P to Dig P.

Table 2

As poultry producers around the world face the challenge of feeding an increasing population with an affordable source of high-quality protein, each player in the production process is forced to revisit current practices and look for opportunities for improvement. Utilization of Dig P formulation is one of those opportunities.

About the Author(s)

You May Also Like