New lab key to effectively developing new products and ensuring quality of existing products.

June 26, 2017

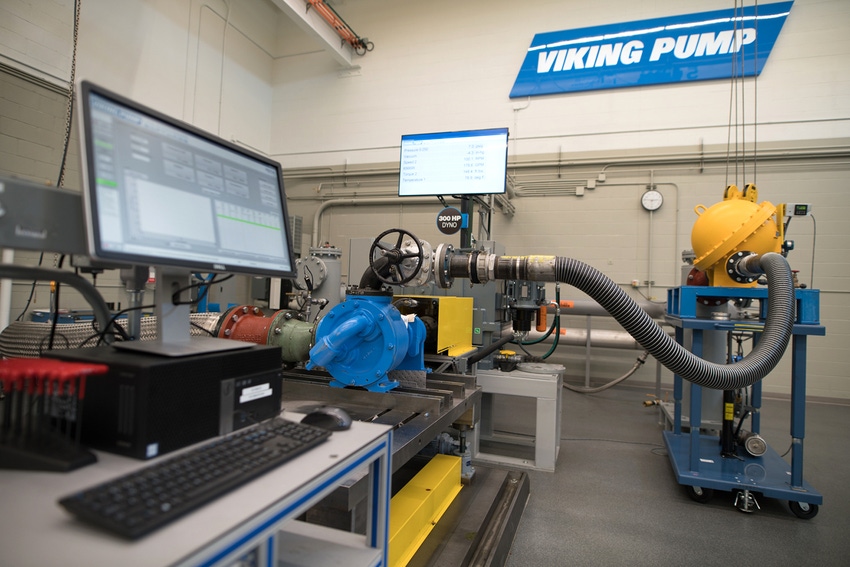

Viking Pump announced that it recently invested $1.75 million to expand its full-service research and testing laboratory, in line with its commitment to provide its customers with innovative pumping solutions for challenging fluid handling needs.

The lab includes a machining/assembly plant, alloy and iron foundries and the original historic headquarters building located near each other in Cedar Falls, Iowa.

The company has been delivering clients the right pump for each situation since its inception in 1911. The announcement said the lab is key to effectively developing new products as well as ensuring the finished goods quality of existing products to meet strict regulatory requirements and maintain customer satisfaction.

In recent years, Viking's growing global footprint started to place more demands on the lab, resulting in the need for efficiency improvements in laboratory operations as well as a larger space to accommodate modernized new equipment and capabilities.

The remodeling project involved adding a total of 3,800 sq. ft. and renovating the original 1,600 sq. ft. to house the following improvements: a 300 hp Dynamometer, two 50 hp Dynamometers, a Distek Data collection of software for five Dynamometers, two 5,600 gal. tanks of testing oil and two 5-ton overhead cranes.

Besides the standard certified performance testing of each pump, Viking's interim president Derrick Goddard said, “Additional testing, depending on the application and product, is also implemented as needed through our new research lab. Finite element analysis is used to optimize component strength, computational fluid dynamics is used to optimize fluid flow through the pump and statistical tolerance stacking software is used to make sure designs are repeatable and to deliver consistent performance from pump to pump.”

John Stillman, Viking distribution business line leader, said along with the new lab environment, “We also developed a scalable new product development process called 'Concept to Customer.' This staged program outlines research, testing, voice of customer and operational and market requirements for the implementation of new products. The program has increased our efficiency as well as guided product development and project funnels for continued research and development.”

Cedar Falls-based Viking Pump, a unit of IDEX Corp., is a leader in the design and manufacture of rotary positive displacement pumps for use in applications ranging from military to food and beverage, chemicals, fuels and plastics.

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)