Managing mycotoxin risks starts with asking the right questions.

November 1, 2020

Sponsored Content

By Brian Arnold, Senior Product Manager — Direct Fed Microbials, United Animal Health

Developing effective strategies for managing risk in swine production systems starts with asking the right questions. What are the inherent risks to the most critical segments of production, and which can I control? What is the potential scope of impact and likelihood these threats may occur? What are my options to minimize these risks? What is the cost and ease of execution of potential interventions?

Proactively addressing these questions can help minimize detrimental impacts to critical production phases that often result in a cascade of downstream shortfalls. Among the many risks that are of concern to multiple management teams across swine production systems is mycotoxins in feed ingredients.

What are the risks with mycotoxins?

Mycotoxins are toxic substances produced by fungi and found in a variety of feed ingredients, creating a multitude of negative impacts on animal health and performance. The scope of damage caused by mycotoxins is dependent on toxin type and concentration, being further exaggerated when additional external stressors are present. For example, fumonisin ingestion during the stresses of weaning or heat stress can lead to further gut damage, opening the door for opportunistic enteric pathogens. This was previously highlighted by Adrienne Woodward in her article, "Fumonisin: The quiet mycotoxin that causes mighty damage."

Mycotoxins, like zearalenone, can also pose a threat to the breeding herd, causing reproductive inefficiencies and additional health challenges, as outlined by Woodward and Julie Mahoney in the article, "Mycotoxins: Don’t be fooled by their impact." Understanding the potential risks to critical production phases is the first step in developing a comprehensive mycotoxin management approach.

Are low mycotoxin levels a concern?

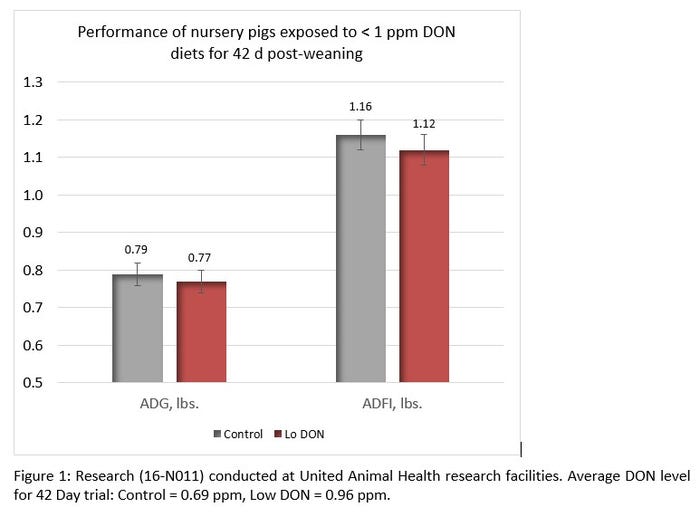

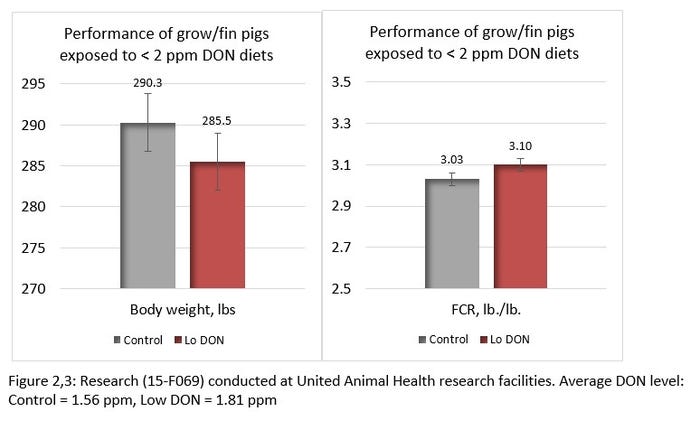

Although Food and Drug Administration advisory levels are established for specific mycotoxins, concentration levels below these thresholds may still prove costly. For example, through research conducted at United Animal Health research farms, a 2.5% reduction in average daily gain and 3.4% reduction in average daily feed intake was observed when deoxynivalenol was increased by as little as 0.25 parts per million in nursery diets (Figure 1). Similarly, in a grow-finish evaluation conducted at United Animal Health research farms, as DON was increased by 0.25 ppm in grow-finish diets, results showed a 4.8-lbs. reduction in body weight and a 2.3% loss in feed conversion rate (Figures 2,3). As the pendulum of profitability in the pork industry has swung in recent weeks from a tumultuous stretch to more favorable near-term markets, mycotoxins, even at perceived low levels, should be considered when looking to fully capitalize on profitability opportunities.

The risk of mycotoxins is not going away.

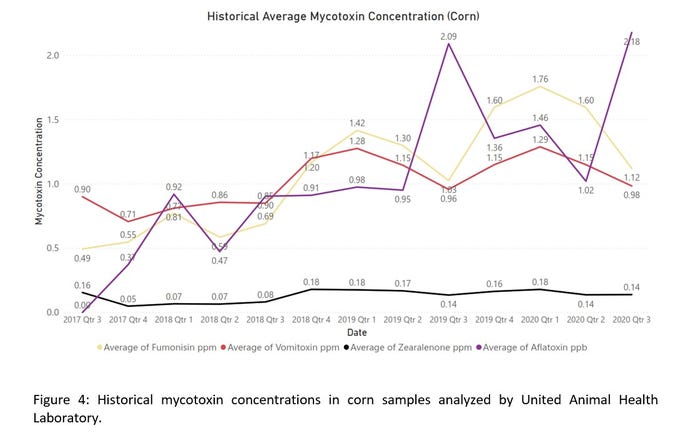

As the 2020 harvest rolls on, the question continues to be asked: What will this year's corn crop look like regarding mycotoxins? While sampling at harvest is important to help establish a baseline, keep in mind that mycotoxin concentrations will continue to evolve. Mycotoxins can continue to grow, even during storage. Toxin profiles may also vary significantly by region, creating challenges with ingredient sourcing. Looking back at historical corn samples analyzed for mycotoxins by the United Animal Health laboratory, one can visually see how mycotoxin levels can fluctuate over time, even within the same corn crop.

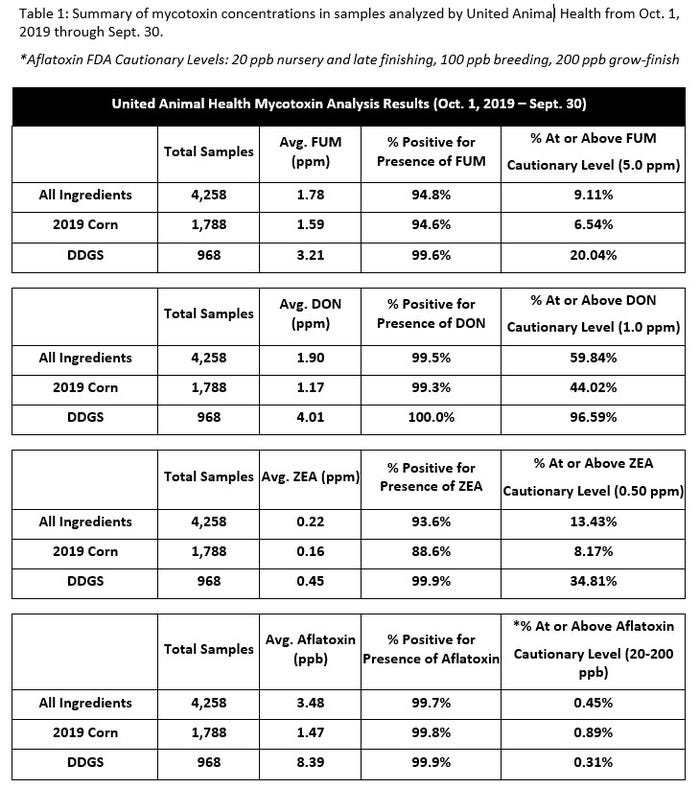

Just how prevalent are mycotoxins in feed ingredients? From Oct. 1, 2019-Sept. 30, 1,788 corn samples were submitted to United Animal Health’s laboratory for mycotoxin analysis from 14 states along with 968 dried distillers grains with solubles samples submitted from 114 different processing locations. One-hundred percent of these samples tested positive for the presence of one or more mycotoxins. Realizing how toxin levels can fluctuate during the growing season, through harvest and during storage, one must recognize that the risks are not going away once corn is harvested and bins are filled.

When developing a mycotoxin management strategy, consider the following questions:

What are the most vulnerable points of production, in which, any negative impacts from mycotoxins may be further compounded downstream?

For many, mitigating the risks of mycotoxins in the breeding herd is critical to protect reproductive fitness at the sow farm and ensure production targets can be met across production segments. Furthermore, understanding mycotoxins impact to wean pig startup, whether by way of reduced feed intakes or through damage to gut health, can shape the need for proactive surveillance and mycotoxin risk management during the nursery phase. Managing grow-finish barn space amid tight fill schedules can be exacerbated by the growth suppression and health challenges caused by mycotoxicosis. Reviewing value drivers and protecting mission critical areas from mycotoxin risks to drive profitability should be a priority.

How can I continually monitor mycotoxin levels in feed ingredients?

Mycotoxin surveillance through sample analysis provides insights into the current mycotoxin profiles of available feed ingredients relevant to specific production locations. The United Animal Health laboratory works closely with account managers and customers to surveil mycotoxin trends over time, across regions and in multiple feed ingredients through sample analysis. Keep in mind, as ingredient sources change, mycotoxin levels will also fluctuate, and toxin levels may also evolve as mycotoxins can continue to form, even during storage.

What interventions can be implemented to mitigate the impacts of mycotoxins in feed?

Good agronomic strategies reduce the incidence of grain stress and damage, reducing the potential for mycotoxin development. Yet, external risks, including extreme weather instances such as this summer's derecho, can be impossible to prevent. Proper grain storage, including lowering corn moisture below 13% and minimizing exposure to additional moisture during storage, can minimize risks of continued mold growth. Mold inhibitors may also serve as a tool to reduce the risk of additional mold growth. However, inhibitors do not reduce toxins that are already present in stored grains. Certain classes of feed ingredients may also serve as tools in the management of mycotoxins and can vary in capability.

Asking the right questions and understanding the risks associated with mycotoxins can ultimately help build a robust mycotoxin management platform that serves as a tool to help meet production goals.

About the Author(s)

You May Also Like