July 1, 2019

Sponsored Content

Aside from being one of the nastiest jobs on the farm, measuring animal waste in pits and lagoons is potentially one of the costliest dangers of managing livestock. In an industry where margins are slim, the price of non-compliance with regulations for waste management can put an operation in jeopardy.

As one owner put it, “The thought of the fines and the publicity that could come from improper waste management is my worst nightmare. There needs to be a better way to monitor and report in an industry where a single breach or spill can ruin my business.”

An Automated Waste Measurement and Alert System

The case for applying technology is a solid one. Automation makes it easier to comply with regulations. High level alerts reduce the risk of spills or breeches. Exportable measurement history streamlines report preparation, simplifying planning and management of application sites.

By capitalizing on an automated approach, you can know when it is time to empty a pit and how much waste is available—allowing a proactive approach in scheduling equipment and manpower. Sensors and software eliminate error-prone and dangerous manual methods of measurement, enhancing safety and efficiency for the entire operation.

How Sensors and Software Simplify Waste Monitoring

Tracking levels on a continuous basis begins with ousting human intervention. Labor is replaced by a radar level sensor that performs reliably in challenging environments. A rugged IP 68 enclosure makes the sensor impervious to dust and weather extremes. Radar measures more consistently than ultrasonic sensors with very high accuracy. If the lagoon gets choppy or wind bounces the sensor, software will average measurements. Solar-powered options are ideal if there is not electrical service available at the lagoon.

Taking the level history and making it useful is the next step. Data from the sensor is processed in the cloud and accessed using a smartphone, tablet, or computer with an internet connection. Each site and sensor location are uniquely named, and the software is able to incorporate multiple sites. Time intervals for measurement frequency and alert conditions are configured in the software. Alerts are sent to staff via a text or email for immediate attention. Reports can be run on demand for specified date ranges. Staff on or off the farm view the same data to make decision-making faster and easier.

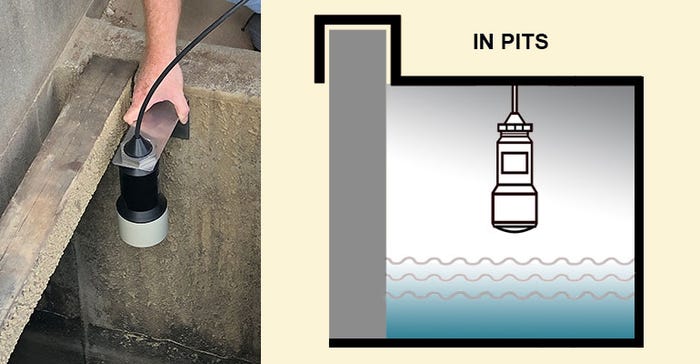

There are several options to install and mount the sensor. For pits, the sensor is wired to a power supply, and a mounting bracket is secured to the pit wall and aimed at the waste.

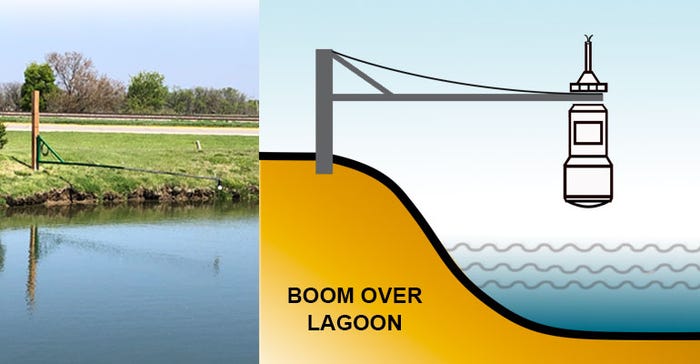

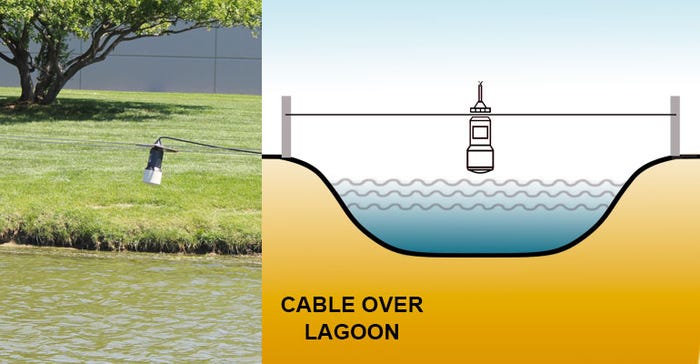

For lagoons, a boom arm is installed on a post with the sensor mounted at the end of the boom. The boom is swung out over the pit and locked into position. Where booms are not well-suited, posts are installed on either side of the lagoon with the sensor mounted on a taut cable suspended across the lagoon.

For hog operations, monitoring pits and lagoons is not a choice. Farmers take this responsibility seriously and are very aware of the consequences. A solution that reduces human intervention and is relatively easy, affordable, and scalable can make compliance less arduous and worrisome for producers.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)