Electric motors are used for a variety of feeding and ventilation functions, making their proper selection key to an operation's success.

August 2, 2016

SPONSORED BY GrowerSELECT

Today’s livestock and poultry operations rely on electric motors for a variety of feeding and ventilation functions. Used in buildings that alternate between dusty and humid, along with fluctuations in voltage and varying workloads, we subject our motors to a very hostile work environment.

When selecting replacement motors, it is important to select motors that are efficient and designed with a “safety factor” that will allow them to last under harsh conditions.

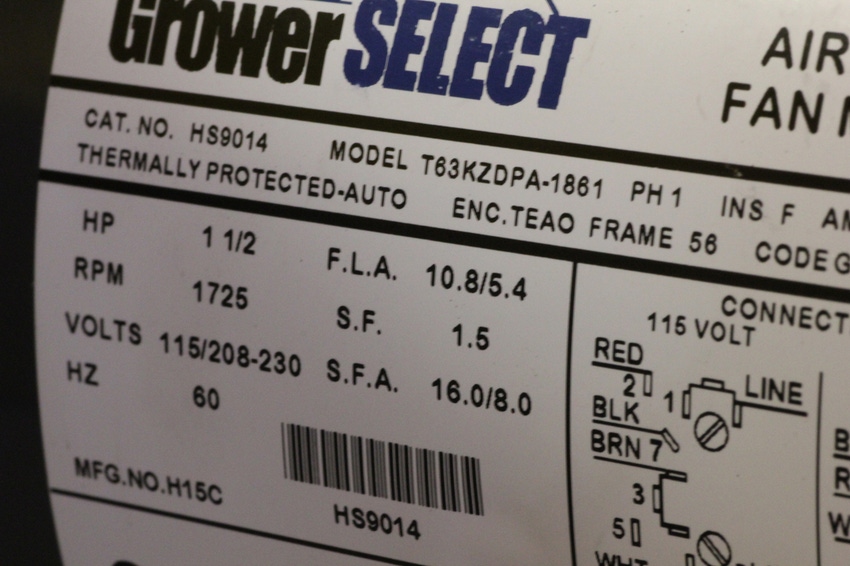

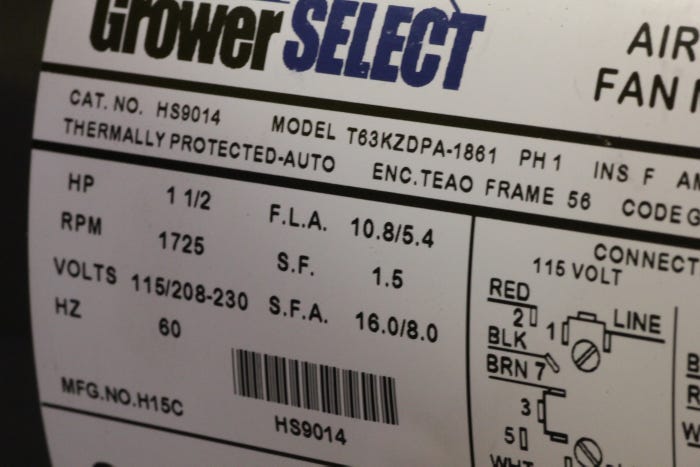

While you may be familiar with the term Service Factor or S.F., there are a couple of important designations found on a motor nameplate that may need more clarification.

Service Factor is defined as a motor's ability to operate under a short-term load. The higher a motor’s S.F. rating is, the more durable the motor. Motors with a high S.F. are expected to last longer. To illustrate, a 1-1/2 hp motor with a 1.5 S.F. can provide 2.25 hp for short-term use. However, it is not a good practice to continuously operate a motor above the rated workload. In other words, the same 1-1/2 hp motor with a 1.5 SF would not be selected to power a 60″ fan that was originally shipped with a 2 hp motor.

Full Load Amps, or F.L.A., represents the amount of current the motor is designed to draw at the rated horsepower. In the example nameplate, this means that when the motor is running under a full load at 230 volts, we can expect it to draw 5.4 amps. Motors with a lower F.L.A. with the same amount of horsepower are considered more efficient to operate.

Service Factor Amps, or S.F.A., represents the amount of current the motor will draw when running at the full Service Factor. In the example nameplate, the S.F.A. is eight amps at 230 volts.

Continually exceeding the S.F.A. shown on the nameplate can shorten motor life. Motors with a higher S.F.A. with the same horsepower have an increased “safety factor” and are expected to last longer under harsh conditions.

The most efficient, rugged motors are designed with a higher S.F., lower F.L.A., and higher S.F.A ratings. By comparing the information on a motor nameplate, we can select the best replacement motors for feeding and ventilation equipment.

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)