New process creates microcapsules that colors milk curds but not liquid whey.

June 29, 2018

Cornell University food scientists have developed an infusion process to give cheddar cheese its consumer-pleasing orange color, according to an announcement.

The new method also preserves whey’s natural color for other commercial uses, the university said, pointing to a published paper in the journal of ACS Applied Materials & Interface.

“Observing cheddar cheese in the grocers’ dairy cases, you see different hues of orange and yellow, and they’re all very popular with consumers,” said Alireza Abbaspourrad, the Yongkeun Joh assistant professor of food chemistry and ingredient technology in the Cornell department of food science.

The hint of tint in cheddar cheese comes from the South America-grown red annatto seed. Adding the seed’s color to milk during the cheese-making process turns the mixture orange or deep yellow, Abbaspourrad said.

Currently, when the curds form, cheese processors are left with an orange-colored whey — the liquid part of milk — which is a valuable protein source. However, as an additive to other foods, whey from cheddar production may not be commercially viable because of its color.

“As whey drains, it still contains a lot of lactose, protein and minerals, which can be a valuable additive when it is spray dried. Food companies can use the powder to add to food products, like infant formula or weight-training drinks, for example,” Abbaspourrad said. “No one wants to use orange-color whey.”

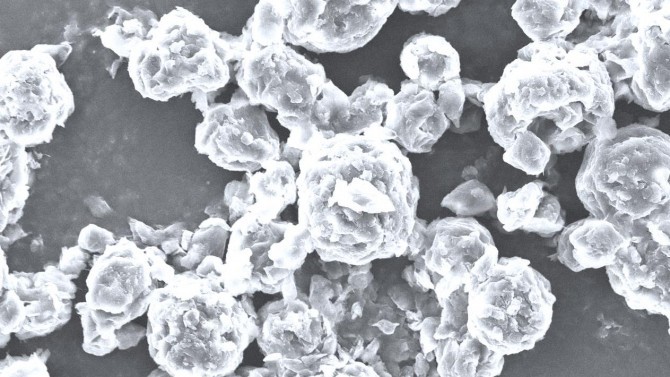

Abbaspourrad’s group has created an annatto-infused microcapsule — coated with a natural shell of casein and a layer of fat — that, when added to milk, befriends the curd and leaves the liquid whey alone.

Inside the curd, microcapsules open during the cheese-aging process. As curds mature, the fat layer is degraded by enzymes that naturally dissolve and release reddish annatto (bixin) to color the curds. “There’s nothing artificial; it’s all natural,” Abbaspourrad added.

The system is quite pliant, Abbaspourrad said, explaining, “The microcapsule shell’s composition is controllable, tunable and can be optimized to use with other enzymes in other food systems or other media.”

Abbaspourrad and co-author, doctoral student Raheleh Ravanfar, filed a provisional patent for the enzymatically triggered microcapsules as a novel method to selectively deliver color to cheddar cheese and obtain white whey powder.

This research, “Controlling the Release from Enzyme-Responsive Microcapsules with a Smart Natural Shell,” appeared earlier this year in the American Chemical Society’s Applied Materials & Interfaces. The study was funded by Dairy Management Inc.

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)