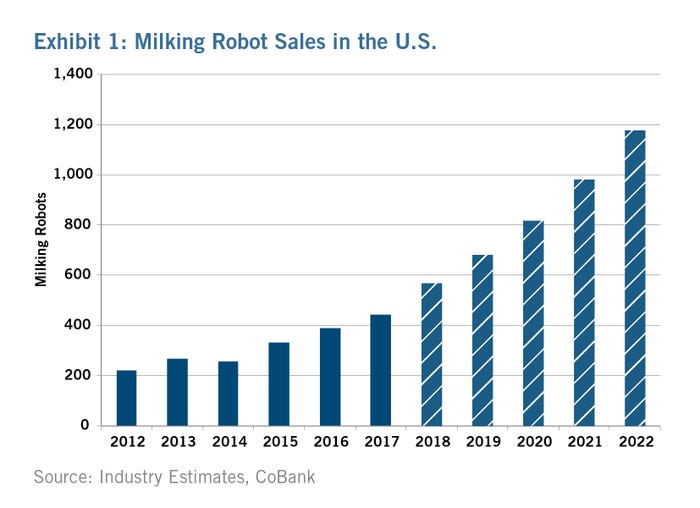

Adoption of robotic elements in milk production expected to grow 20-30% annually.

March 27, 2018

Various forms of robotic milking are helping sustain small- to medium-sized dairy farms amid broader industry consolidation and improving labor efficiency for some larger operations, according to a new report from CoBank’s Knowledge Exchange Division.

Dairy robots, also referred to as automated milking systems, take a variety of forms. From “box”-style units to robotic components on rotary-style milking parlors, they all provide an alternative to traditional dairy labor, which has become more expensive and harder to find in many regions of the U.S., the report explains.

“Labor and finance are two of the most important issues when large farms are considering dairy robotics, but when I spoke to smaller-scale producers, the primary drivers of adopting this technology were around quality of life,” CoBank senior analyst Ben Laine said. “However, the future growth of this technology and possible broader adoption will be centered on labor costs, milk production per robot and proximity to dealers and service technicians.”

A single box-style unit can cost around $200,000 without housing, and the target production for one unit is 4,500 lb. of milk per day.

“As the technology improves and labor costs increase, we will see the trade-offs continue to shift in favor of robotics,” Laine said. However, “there is still plenty of uncertainty around useful life of the units and milk production efficiency that will give many producers pause.”

A brief video synopsis of the report, “Automatic Milking Systems: Keeping Smaller Dairies in the Game,” is available here, and the full report is available at CoBank.com.

You May Also Like