Variation in the quality of protein sources prevents you from accurately predicting performance and limits the production of your dairy herd. Learn how to minimize the impact of this variability and improve profitability.

February 6, 2019

Sponsored Content

High variability found in certain protein sources can negate the effort to accurately predict the supply of nutrients, resulting in yields of milk and components that seldom meet expectations. Current nutritional models simply cannot account for the variation in quality and this directly impacts the accuracy of the predictions.

Feed ingredients brought into formulations to source RUP are often the most variable, chiefly due to processing. The heating process that is intended to increase the supply of RUP can render the protein or specific amino acids completely undigestible or un-usable by the cow. Among the 10 essential AA, lysine is extremely vulnerable to being altered or even destroyed during heating. This is due to its additional amino group that can easily bind sugars under heat conditions, in what is known as browning or Maillard reaction. This uncertainty makes it very difficult to meet metabolizable protein or MP Lysine requirements aimed to maximize production without overfeeding costly feed protein.

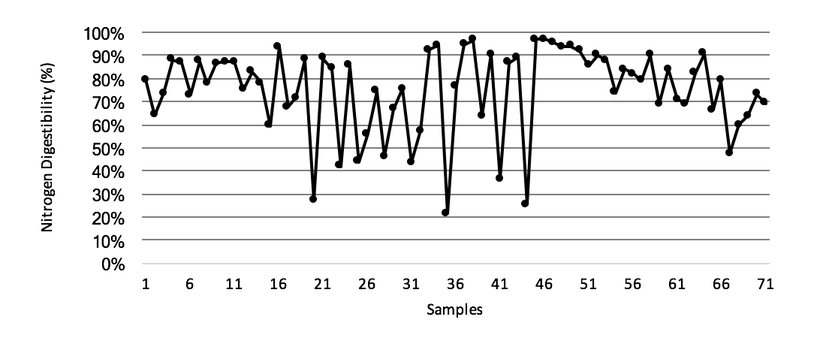

Just how variable are high RUP protein sources? Kemin Industries has tested over 70 blood meal samples using the In Vitro Nitrogen Indigestibility Assay (IVNIDA) developed by Ross et al. (2013). In this assay, nitrogen digestibility is used to evaluate the availability of the protein supplied by the blood meal. Additionally, intestinal availability of the lysine contained in the RUP is determined. On average, the nitrogen that can be digested and utilized by the cow, is close to expected values at 75%. In other words, on average 25% of the nitrogen contained in the blood meal could not be used and was simply excreted into the environment.  However, the variation in digestibility was huge, and ranged from 22 to 97%. Meaning that, worse case almost 80% was not available to the cow and excreted in urine, the most labile form of nitrogen excretion. The variability in lysine content was just as eye opening, 73% of the total lysine was digestible with a range from 0 to 97%. In some cases, the damage done to lysine digestibility during the heating and processing of blood meal resulted in total destruction of the contained lysine.

However, the variation in digestibility was huge, and ranged from 22 to 97%. Meaning that, worse case almost 80% was not available to the cow and excreted in urine, the most labile form of nitrogen excretion. The variability in lysine content was just as eye opening, 73% of the total lysine was digestible with a range from 0 to 97%. In some cases, the damage done to lysine digestibility during the heating and processing of blood meal resulted in total destruction of the contained lysine.

Variability in digestible protein or lysine availability is not confined only to blood meal. A recent presentation at the 2017 Animal Nutrition Conference of Canada identified a significant difference in the lysine content among canola meals (Rahmani, et al 2017). The way soybean meal is processed can also impact its ability to provide digestible protein and essential amino acids like lysine (Borucki, et al 2007). This inconsistency negatively affects the ability of a nutritionist to accurately formulate diets and maximize profits.

While each of these protein sources provide valuable nutrients, the amount of intestinally available lysine or MP lysine that is supplied is a major concern. The use of a rumen protected lysine reduces your reliance on inconsistent ingredients, decreases the variability in the MP lysine supply and helps to meet MP lysine requirements in a consistent, cost effective manner. This can improve the accuracy of milk and milk component predictions and overall profitability of your client’s dairy operation.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)